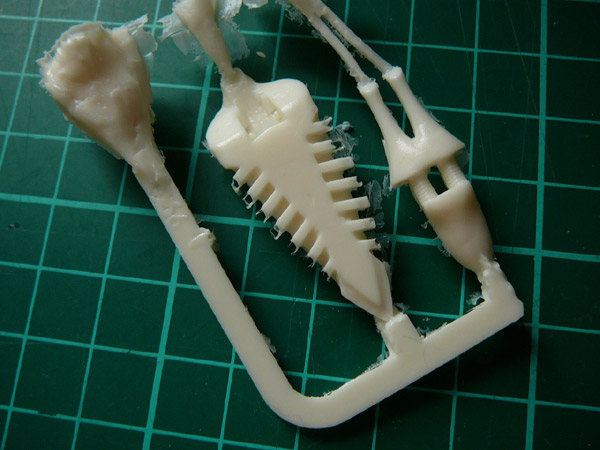

An update on casting. I hit a snag where the mold seemed to get better technically which perversely led to creating worse casts. After about 4 or 5 successful casts, they started to come out looking like this:

Note 2 things, firstly that there are some really nasty air bubbles forming in the vanes on the canopy underside, rendering the piece virtually unusable, and secondly there is way less flashing. I postulate that the large amount of flashing I first experienced was actually part and parcel of getting a full, clean cast – any air was being forced between the halves of the mold as the flash formed.

To try and solve this I cut some more air channels in the mold, one extending from each vane and then joining a master air channel that leads up to the main air vent for the canopy underside:

This seemed to solve the problem. I’m now getting clean casts and the flash is back! I can’t say exactly what else I may have done differently. Possibly making sure the elastic bands that hold the mold together are located at the top and bottom of the mold, rather than around the middle where the parts are, is also important, as they may have been compressing the mold too much, thus eliminating the flash (and space for the air to flow).

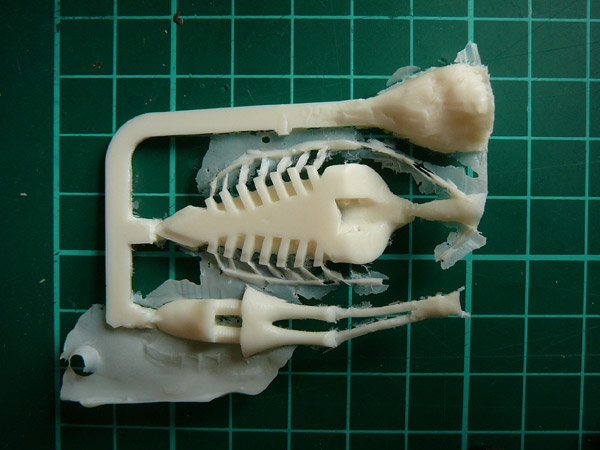

Pile o’ bits!:

In other news I think I may have screwed up the Warlock leg mold hugely, by not mixing the rubber properly. I poured it last night (in poor light) and this morning I see there are streaks in the mix and it is still sticky to the touch – not a good sign. I don’t relish digging through half cured rubber to find and then clean the legs…